plastic pellet processing solutions

Request a Quote

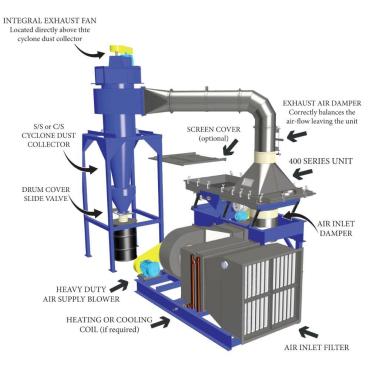

400 Series Plastic Pellet Classifier

If the ultimate post-plastic pelletizing processing is desired, look no further than the Witte 400 series plastic pellet classifier. Combining our expertise with fluid beds and plastic pellet classifying, the 400 series fluid bed cooler and plastic pellet classifier is capable of multiple functions in one compact unit.

Related Resources and Downloads

Functions include:

- Air Classification: Almost total removal of any minus 20 mesh "fines" including those statically held. High velocity air combined with our converging exhaust cover allow nuisance fines to be swept away and out of your final product.

- Cooling: Pellets can be quickly cooled using only ambient air from our plastic pellet cooler. Cool pellets do not stick together and do not cause problematic condensation issues in a sealed package.

- Drying: Residual surface moisture can be removed with ambient air if the pellet temperature is 185 F or greater. In other cases, heat can be added to bring the pellet moisture content down to specification.

- Fines Removal: Larger fines that are not removed in the fluid bed air section are taken out with either a perforated or wire mesh fines screen.

- Oversize Removal: A traditional perforated deck is used to remove any oversize and longs. Dual, redundant perforated decks can be used to increase screening efficiency.