The Witte Company Upgrades Fabrication Equipment to Ensure Equipment Excellence

In order to produce the highest quality processing equipment at a competitive price, The Witte Company has purchased three new CNC manufacturing machines over the past year.

These machines are comprised of the following:

- 3 KW fiberoptic laser cutter: The new laser cutter produces very high plate and sheet cut quality for better part fitment and finished weld quality. Metal parts can be fitted together and welded directly after cutting with no secondary part preparation or grinding required. Finished weldment dimensions have tighter dimensional tolerances with less times required.

- 175 Ton Hydraulic CNC Press Brake: This new press brake has a full CNC control package for more accurate and repeatable bends. A fully automated backstop allows operators to bend a part using only the graphical interface, eliminating the need for bend lines. [see picture B]

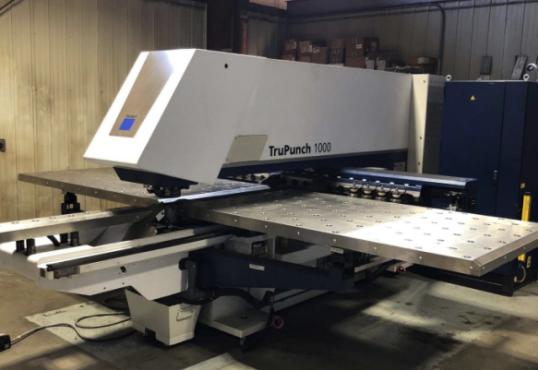

- 18.5 Ton Hydraulic CNC Punch: This automated punch press is used to create precise perforated patterns used on Witte equipment. These patterns are used for our vibrating classifier screens and to create air distribution decks on our fluid bed dryer. [see picture C]

All three machines can be programmed offline to maximize efficiency and repeatability. The Witte Company would be happy to help you with any of your metal fabrication needs.

time-tested technology proven to work as specified